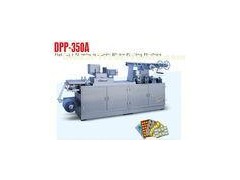

Save Material Aluminum Pharmacy Blister Packaging Machine PRC System

Specifications

| Model | 350A | |

| Machine Body | Stainless Steel 304/316 | |

| Blanking frequency(times/min) | 15-45 | |

| Blister plats size | Design according to customers’ requirements | |

| Adjustable pulling length | 30-140mm | |

| Max Forming area and depth(mm) | 350*200*50 (Private custom) | |

| Air compressor(Don't Provide) | 0.6-0.8Mpa ≥0.6m3/min | |

| Mould cooling (Recycle water or circulating water consumption) | 60-100 L/h | |

| Power supply(Three phase) | 380V/220V 50HZ 12KW | |

| Wrapper specification(mm) | PVC | 350*(0.15-0.6)*(Φ400) |

| PAP | 350*(50-100)g/m2*(Φ400) | |

| Overall Dimension(L*W*H)(including foundation) | 3650×850×1700 | |

| Dimension of Each Part | 1850×850×1700(front) | |

| 1800×850×1650(back) | ||

| Weight | about 2000kg | |

Description

- Pulling length can be adjusted. Mold is fixed by located groove so that it's easy to change mold.

- The machine heats the PVC through heated board and forms by compressed air frothing.

- Speed is controlled by inverter. It Adopts the interface of human machine and PLC controller. Adopt universal feeder for feeding.

- The machine gets the function for Easy Cutting line embossing, batch number embossing and wasted packaging material rewinding.

- Step motor is adopted on the machine for precise controlling on pulling length and saving packing material.

- The heating molds will automatically separate when the machine stops, which contributes to protect the packing material from heated mould.

Applications

The DPP-A blister packing machine is a newly packaging machine designed for machine in our company; its function has reached domestic leading level. It is suitable for capsule, tablet, big honey pill, candy, liquid, paste, one injector as well as irregular shape Al-plastic, paper-plastic composite packaging in pharmacy, healthcare, food, cosmetics, medical equipment industry etc.

Save Material Aluminum Pharmacy Blister Packaging Machine PRC System